Nonmetal filter is mainly divided into two types: prefilter, also known as security filter, terminal filter, also known as precision filter. Filter elements of different forms and materials shall be configured according to the filtering purpose, medium conditions. The cylinder is made of high-quality 304 or 316 stainless steel, which can be installed with filter elements of different specifications and models according to the filtering purpose, medium conditions, configuration of different forms and materials: the filter, such as GMP pharmaceutical water, can be used in series with two groups of 5um and 0.22um folded membrane cylinder filter elements; In the fermentation industry, air filtration can remove bacteria and phage from the air, and can also seal the exhaust gas for treatment, meeting the American Standard of bacteria filtration him.

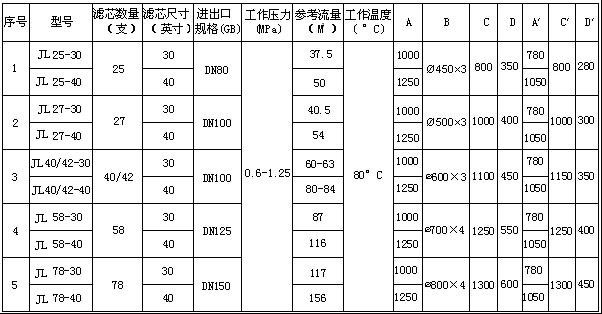

Filter element parameters:

Filter material: polypropylene film (PP) filter, polytetrafluoroethylene film (PTFE) filter, cellulose acetate film (CN-CA) filter.

Filter element precision: 0.1-60um (μ m)

Filter element length: 10 "20" 30 "40" (i.e. 250mm 500mm 750mm 1000mm)

Pressure resistance of filter element: 0.42m.pa, supporting recoil.

Filter element interface mode: 222 (flat nozzle type) 226 (plug-in type)

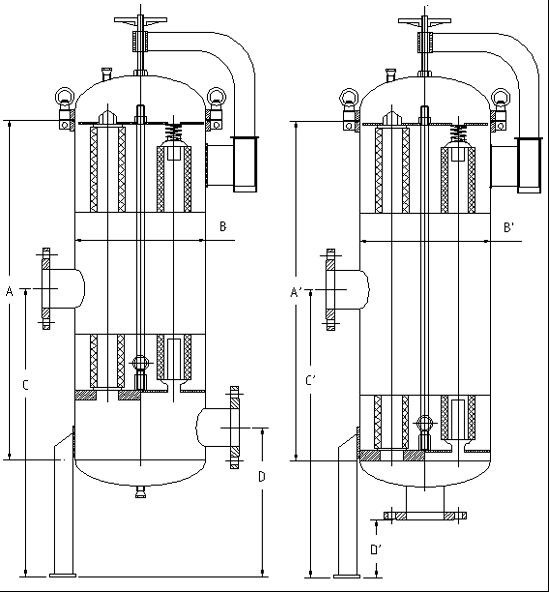

Filter parameters:

Inner surface: Ra0.2Um

External surface: polishing treatment, matte treatment

Theoretical filtration flow: 0.5t/h-25t/h

Pressure range: 0.1m.pa-1.0m.pa 1-10bar

The filters are: 1 core, 3 cores, 5 cores, 7 cores, 9 cores, 11 cores, 13 cores, 15 cores, etc

Filter height: 10 "20" 30 "40"

Common filter material: polytetrafluoroethylene (PTFE) polyester (PE) nylon (nylon) polypropylene (PP)

Filter aperture: 0.1um 0.22um 0.45u 1um 3um 5um 10um

Material: SUS304, Sus 316L

Due to different applications, it can be divided into the following two types of filter elements: hydrophobic (for gas) hydrophilic (for liquid)

The practice proves that the microporous membrane filter produced by our company can filter out the particles and bacteria above 0.1um in the liquid and gas. It has the advantages of high filtration accuracy, fast filtration speed, less adsorption, no medium falling off, no pollution, good thermal dilution stability and chemical stability, acid resistance and corrosion reduction, easy operation, etc. In particular, small volume, light weight, small floor area, large filtering area, low blocking rate, fast filtering speed and so on, have relieved the troubles for the majority of users.

Size, height, wall thickness, pressure can be customized according to customer requirements.

Application fields:

1. Nanofiltration (NF), ultrafiltration (UF), reverse osmosis (RO), electrodialysis (EDI) and other system security filtration and terminal filtration;

2. Filtration of medical injection, infusion, eye drops, Chinese herbal medicine, extraction, purification and concentration of biological agents;

3. High purity water pre filtration and terminal filtration for electronic, microelectronic and semiconductor industries;

4. Oil field reinjection water, boiler feed water, chemical reagents, liquid organic products, high-purity chemicals, concentrated drugs and other filtration;

5. Filter purified drinking water, mineral water, fruit juice, tea drinks and health drinks;

6. Filtration of white spirit, wine, beer, yellow rice wine and other fruit wine, sterilization and filtration of pure draft beer

7. Pretreatment filtration or security filtration in the process of production, domestic wastewater treatment and reclaimed water recycling;

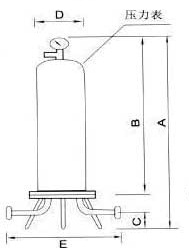

Industrial safety filter

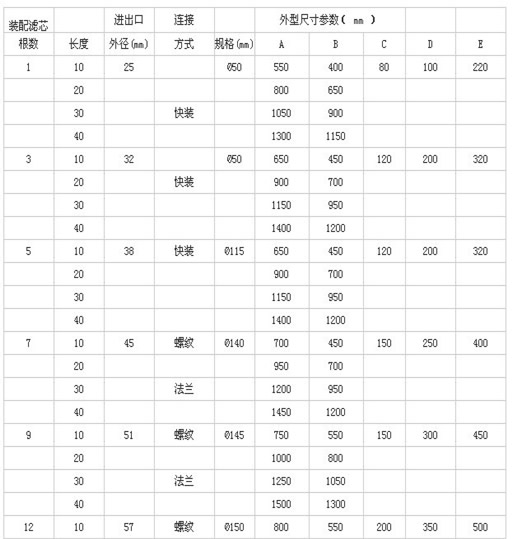

Sanitary safety filter

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI