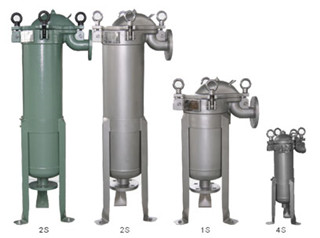

Cast single bag filter and high pressure tortoise back bag filter are the most popular and praised single bag filter on the market at present because of their ingenuity and simplicity, and they are optimized to the best performance by using the most advanced precision casting die jacking filter structure.

_Better sealing effect to prevent side leakage

_Large effective filtering area and higher filtering efficiency

_Easier and faster replacement of filter bags with lower operating costs

_Reasonable structure and more stable filtration

_Adjustable installation height to suit space requirements for specific applications

_Personal language design, all for you

Features of Jacking-in cast filter

1. The internal space of the filter is used more fully to eliminate the space waste existing in the traditional side feed type.

2. The filter bag can be replaced quickly by opening the upper cover. Unlike the traditional side-feeding machine, the filter bag pressure ring can not be replaced until it is removed, which reduces the chance of secondary pollution.

3. The liquid inlet pipeline is wide and smooth, and the top cover is horn-shaped inside; when the liquid enters, it can automatically divide the pressure; it has little impact on the filter bag, effectively protects the filter bag from accidental occurrence, small pressure loss, faster and more stable filtration;

4.The filter bag uses patented ring opening, which is close to the filter and won't loosen; multi-seal makes the sealing effect better.

Product Application Range

Water treatment (1) removing sand particles from seawater; (2) ion exchange resin recovery; (3) system purification in cooling device; (4) cooling water purification in power plant; (5) removing sludge from mineral water; (6) filtering chemicals used for water treatment

Food and beverages (1) filter stabilizers in beer; (2) purify wine, whisky and beer; (3) remove impurity particles from edible oils; (4) remove carbon inks from cellulose; (5) filter industrial sugar canes;

Chemicals (1) filtration of catalysts; (2) filtration of acid and alkali solutions; (3) removal of carbon inks and filter aids; (4) removal of emulsions and suspensions; (1) removal of gels from acrylic binders; (2) removal of resins and crystals; (3) filtration of varnishes and topcoats; (4) filtration of pre-treatment phosphates and water; (5) filtration of electrophoretic paints and pre-treatment solutions.

Product Details

|  |

Technical parameter

Model | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | Max. flow rate(m3/h) | Connection mode of import and export | |

Max | Min | ||||||||

SQ-1P1S | 790 | 847 | 723 | 588 | 495 | 415 | 260 | 20 | DN50 flange |

SQ-1P2S | 1530 | 1217 | 958 | 958 | 865 | 785 | 260 | 45 | DN50 flange |

SQ-1P3S | 376 | 356 | 296 | 296 | 232 | 182 | 150 | 5 | 1″NPT |

SQ-1P4S | 676 | 611 | 466 | 466 | 382 | 332 | 150 | 10 | 1″NPT |

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI