The automatic brush filter is an indispensable treatment means in the process of water purification, which is used to intercept the impurities in the water, purify the water quality and protect the normal operation of other equipment in the system.

Ordinary mesh filter is widely used in water source filtration, industrial circulating water system and other fields because of its good filtering effect and small resistance. Its disadvantages are small pollutant holding capacity and easy blockage

Plug, low degree of automation, complex cleaning work, it is necessary to shut down the machine and disassemble the equipment to realize the cleaning of the filter part, which greatly reduces the self-cleaning of the whole system

The degree of mobility seriously restricts the production efficiency of users. With the deepening of understanding, most of the industrial and mining enterprises in the world are looking for and using a

Higher automation, with its own cleaning function filter to replace the original backward equipment.

SLF series self-cleaning filter is an intelligent full-automatic filter with the world's leading technology. Compared with the previous filters, it has a high degree of automation and processing capacity

Large, self-cleaning sewage, uninterrupted water supply, widely used and other advantages. The product has the advantages of high filtering accuracy, short cleaning time, less water consumption and small pressure loss

You provide stable and reliable water quality assurance. The filter is equipped with powerful intelligent control system and self-cleaning device driven by electric power. Control system standard large screen color

Chinese LCD touch screen, the system has its own operation manual, which is very convenient for your use. At the same time, it can display the running status of the equipment online in real time and reserve the output connector

It can realize remote monitoring function. The machine also has overload protection, no-load protection and alarm functions, so that you can safely use this product.

|  |

|  |

Filtration process

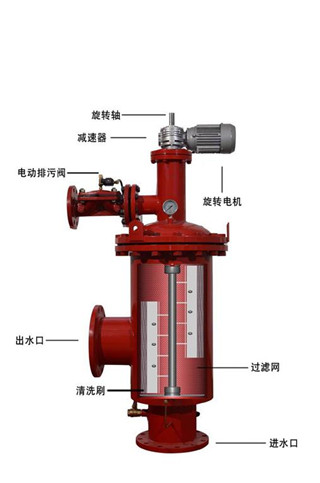

The raw water flows into the filter cartridge from the water inlet, enters the filter cartridge, and then passes through the filter cartridge from the inside out. The impurities are blocked on the inner wall of the filter cartridge. The filtered clean water flows out from the water outlet. When the impurities on the inner wall of the filter cartridge accumulate more and more, the filter cake is formed on the inner surface of the filter cartridge, and the differential pressure is gradually formed inside and outside the filter cartridge. When the differential pressure reaches the preset value of the differential pressure controller, the self-cleaning will be started Cheng.

Self cleaning process

The self-cleaning process of the filter depends on the cleaning brush and the blowdown valve which rotate along the inner surface of the filter cartridge. The opened blowdown valve causes a negative pressure in the blocked filter cartridge, and the filter cake attached to the inner wall of the filter cartridge is cleaned by the cleaning brush. Because of the negative pressure, the filter cake is discharged outside the filter cartridge by the blowdown valve. The whole cleaning process is about 60 seconds, and the system does not cut off when cleaning.

control mode

SLF series self-cleaning filter operation is equipped with three functions of differential pressure / time / manual. At the same time, we specially designed the priority control function for you, that is, in any case, as long as the system differential pressure reaches the predetermined value, the equipment will start the self-cleaning function, so as to better ensure the normal operation of your system.

Application scope

Industrial filtration application: source water cooling water, reclaimed water and side filtration water, circulating water of refrigeration and heating system, cooling water and chilled water filtration of chemical industry, iron and steel industry, paper industry, power plant, automobile industry, water plant and other industries; protection nozzle; three-level sewage treatment; municipal water reuse; workshop water; R.O. system front filtration, etc;

Application of irrigation filtration: groundwater; municipal water; rivers, lakes, seawater; orchard; nursery; greenhouse; golf course; park, etc.

SLF self cleaning filter (FL Series) model description

SLF (self cleaning filter) / (type) - caliber - filtering precision / design pressure

Product characteristics

■ the maximum filtration flow of a single unit can reach 4000m3 / h

■ filter accuracy from 4000 microns to 20 microns

■ the filter screen can be drilled (4000-800 μ m), wedge-shaped (1000-50 μ m) woven composite (800-20 μ m)

■ minimum working pressure ≥ 0.1MPa

■ maximum working pressure ≤ 1.6Mpa (special customizable)

■ working temperature ≤ 95 ℃

■ power supply: 380V / 50Hz

■ control voltage: AC24V

■ cleaning method: electric brush type.

■ control mode: differential pressure, time, manual and PLC

■ cleaning time: 10-1000 seconds adjustable

Product selection

In order to better adapt to the technical requirements of your water system and the best filtering effect, and meet the requirements of water saving, power saving, energy saving and environmental protection, when choosing self-cleaning filter, please consider the following parameters:

1. Processing flow

2. Filtering accuracy

3. Pipe pressure

3. Chemical properties of filter media

4. Suspended solids concentration of filter medium

SLF electric brush type self-cleaning filter SL series filter precision comparison table

μm | 10 | 25 | 30 | 40 | 50 | 80 | 100 | 120 | 150 | 200 | 400 | 800 | 1500 | 3000 |

Mesh number | 1500 | 650 | 550 | 400 | 300 | 200 | 150 | 120 | 100 | 80 | 40 | 20 | 10 | 5 |

SLF electric brush type self cleaning filter SL series technical data sheet

Model | Import and export (mm) | L (mm) | L1 (mm) | L2 (mm) | H (mm) | D (mm) | Sewage outlet (mm) | Flow (m3/h) | Weight (Kg) |

SLF-80 | 80 | 500 | 1040 | 1270 | 317 | 273 | 40 | 50 | 148 |

SLF-100 | 100 | 520 | 1040 | 1270 | 317 | 273 | 40 | 80 | 151 |

SLF-125 | 125 | 540 | 1090 | 1320 | 342 | 325 | 40 | 105 | 255 |

SLF-150 | 150 | 560 | 1090 | 1320 | 342 | 325 | 40 | 150 | 260 |

SLF-200 | 200 | 460 | 1100 | 1330 | 354 | 378 | 50 | 320 | 315 |

SLF-250 | 250 | 700 | 1340 | 1570 | 463 | 426 | 50 | 450 | 445 |

SLF-300 | 300 | 800 | 1490 | 1720 | 565 | 530 | 50 | 600 | 495 |

SLF-350 | 350 | 900 | 1640 | 1870 | 665 | 630 | 50 | 850 | 570 |

SLF-400 | 400 | 1000 | 1790 | 2020 | 720 | 760 | 80 | 1200 | 645 |

Note: this data is for reference only, subject to the material object. It is subject to change without notice | |||||||||

SLF electric brush type self cleaning filter SL series filter material

■ shell: carbon steel, 304 stainless steel, 316L stainless steel

■ filter screen: 304 stainless steel, 316L stainless steel

■ cleaning brush: stainless steel, nylon

■ drain valve: cast iron, copper, stainless steel

■ controller: PVC, aluminum

■ sealing ring: EPDM rubber

Note: other special materials can be customized according to customer's requirements. Please consult our company for details.

Equipment installation and connection

(1) During installation and use, pay attention to the protection of control box, sensor and transmission part to prevent damage.

(2) Connect the pipeline according to the direction indicated by the arrow on the self-cleaning filter body, so that the water flow direction is consistent with the arrow on the body. SL series self-cleaning filter has two installation forms (see the figure below). When any installation form is adopted, attention shall be paid to make the outlet direction of automatic drain valve horizontal or downward to ensure more thorough drainage.

(3) The self-cleaning filter shall be installed before and as close to the water equipment as possible.

(4) In the power system, the self-cleaning filter should be installed between the water pump and the water equipment, the closer to the water equipment, the better. When the pressure in front of the pump and water equipment exceeds the limit pressure of the filter, the self-cleaning filter can also be installed in front of the water pump as close as possible to the water pump.

(5) The connection mode of automatic blowdown valve is divided into flange and screw thread. The blowdown pipe should not be too long, and it is better not to exceed 10 meters.

(6) The installation shall be convenient for maintenance. The shut-off valve shall be installed before and after the self-cleaning filter, and the bypass pipe shall be installed.

(7) The specification of self-cleaning filter shall match with the pipeline or flow. When a single filter cannot meet the flow requirements of the system, two or more filters can be connected in parallel to meet the system filtration requirements.

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI