Vertical blade filter, vertical plate type closed filter and blade diatomite filter are of high efficiency

The energy-saving and hermetically operated precision clarification and filtration equipment adopts double-sided filter plate (built-in 5-layer filter screen) and vertical installation, which not only reduces the cost of the equipment, but also creates favorable conditions for rapid slag discharge. It is especially suitable for the occasion where the viscosity of filter residue is not high or wet discharge process is adopted. With the same filtering area, the volume of other closed filter equipment is reduced by 40%, and the vertical installation is convenient for vibration slag removal. It is widely used in salad oil, mechanical crude oil, chemical industry, petroleum, coating, food, pharmaceutical and other industries.

Characteristics of blade filter

1. Small size, high efficiency, low cost and less investment.

2. Totally enclosed operation, no pollution, no material loss.

3. The filter plate made of stainless steel does not need filter paper and cloth, thus greatly reducing the filtering cost.

4. Pneumatic vibration slag dropping device can realize automatic slag unloading and continuous operation.

5. Pneumatic and actuated butterfly valves discharge slag, greatly reducing the labor intensity of workers.

Application range of plate type closed filter

Oil industry: mechanical crude oil filtration, rabbit oil filtration, hydrogenated oil filtration, winter oil filtration, etc

Food industry: decolorization and filtration of sugar solution such as sugar and glucose, clarification and filtration of alcohol, juice and beverage, etc.

Chemical industry: crystal separation in various filtration processes of petrochemical industry, inorganic chemical industry and organic chemical industry, filtration and separation of various catalysts,

Decolorization and filtration of chemical products.

Site photo of plate type closed filter:

|  |

|  |

|  |

| Technical specifications of plate type closed filter (vertical vane filter) | ||||||||||

Model | Filtration area | Cake volume | Processing capacity(T/h.m2) | Working pressure(Mpa) | Working temperature | Volume of filter cylinder | Body weight | |||

Edible oil | Resin | Drinks | Rated pressure | Max. pressure | ||||||

VBF-2 | 2 | 30 | 0.4-0.6 | 1-1.5 | 1-3 | 0.1-0.4 | 0.6 | ≤150 | 120 | 300 |

VBF-4 | 4 | 60 | 0.5-1.2 | 2-3 | 2-5 | 250 | 400 | |||

VBF-7 | 7 | 105 | 1-1.8 | 3-6 | 4-7 | 420 | 600 | |||

VBF-10 | 10 | 150 | 1.6-3 | 5-8 | 6-9 | 800 | 900 | |||

VBF-12 | 12 | 240 | 2-4 | 6-9 | 8-11 | 1000 | 1100 | |||

VBF-15 | 15 | 300 | 3-5 | 7-12 | 10-13 | 1300 | 1300 | |||

VBF-20 | 20 | 400 | 4-6 | 12-17 | 1680 | 1700 | ||||

VBF-25 | 25 | 500 | 5-7 | 16-21 | 1900 | 2000 | ||||

VBF-30 | 30 | 600 | 6-8 | 19-25 | 2300 | 2500 | ||||

VBF-36 | 36 | 720 | 7-9 | 23-31 | 2650 | 3000 | ||||

VBF-45 | 45 | 900 | 8-11 | 30-38 | 3200 | 3500 | ||||

VBF-52 | 52 | 1040 | 9-13 | 36-44 | 3800 | 4000 | ||||

VBF-60 | 60 | 1200 | 10-15 | 42-51 | 4500 | 4500 | ||||

VBF-70 | 70 | 1400 | 11-17 | 48-60 | 5800 | 5500 | ||||

VBF-80 | 80 | 1600 | 12-19 | 56-68 | 5860 | 6000 | ||||

VBF-90 | 90 | 1800 | 13-21 | 64-78 | 6700 | 6500 | ||||

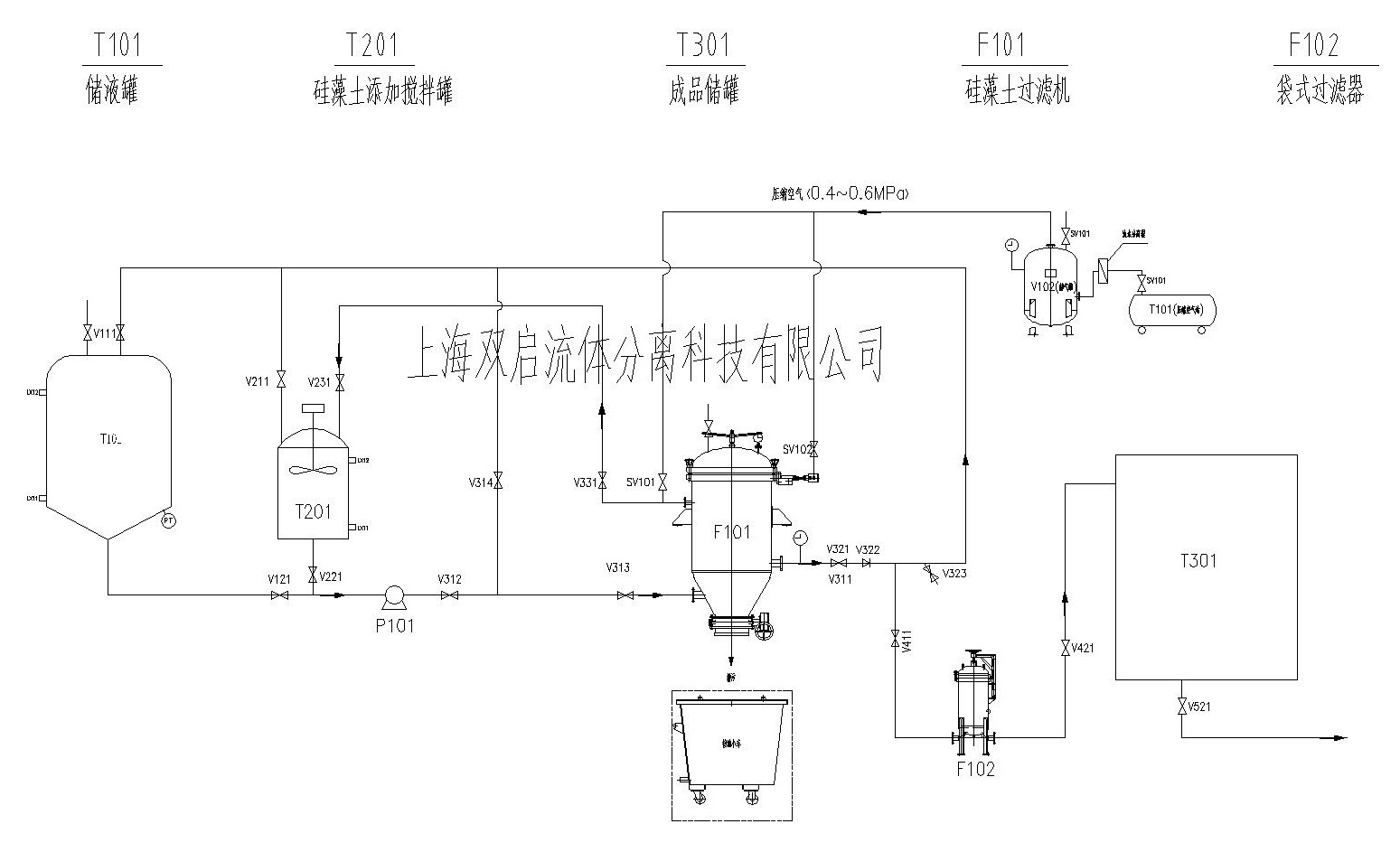

Flow chart of plate type closed filter (blade filter)

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI