Automatic scraping-type self-cleaning filter (GZF)

Product Description and Use:

Product Description and Use:

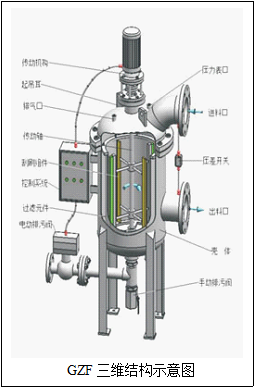

The GZF series of fully automatic wiper type self-cleaning filter is composed of motor reducer, filter case, filter screen, wiper combined cleaning system, PLC controller and electric sewage discharge valve and other components. The raw material medium enters the filter through the feed port, through the filter outside, the filter clearance is filtered, and the filtered raw material flow from top down to the lower outlet. The impurities between the filter mesh are trapped after the filter assembly runs for a certain time. The scraper type self-cleaning filter has a reasonable layout and the scraping Angle is optimized. Driven by the deceleration motor, the rotating scraper has scraped off the impurities in the filter gap in time to avoid the trouble of dismantling and washing the filter screen and keep the raw materials unimpeded and filtering. The scraper system consists of fixed plate, PTFE scraper brush combined cleaning composed of self-cleaning filter and spring, the spring pressure compensation selection is reasonable, to minimize the wear on the filter screen.GZF automatic self-cleaning filter is suitable for the filtration of high solid content, fibrous impurities and high viscosity fluid.

Product characteristics

1. The Angle formed by the scraper system and the wedge mesh rotates to produce the shear force, remove the impurities of the filter net and discharge them with the opening of the sewage discharge valve. The wedge filter net is cleaned and not easy to wear;

2. Adopt automatic online continuous filtration to meet the requirements of process operation;

3. The system adopts electric drive: use the reducer to drive the rotary wiper cleaning system, automatically remove the impurities attached to the filter screen, and maintain the filter filter function

4.PLC control function: the differential pressure cleaning, regular cleaning, manual cleaning; and the differential pressure is preferred, and can be connected with the central control room;

5. Flexible sewage discharge methods can be set according to the different material viscosity or the requirements of other process parameters:

Product application scope

1. Industrial circulating water: circulating water, condensate water and cooling water for blast furnace, rolling mill, continuous casting machine in iron and steel industry

2. Raw water filtration: seawater desalination, river water, surface water, and incoming water treatment

3. Environmental protection engineering: pre-filtration of bag, core, UF, RO film and other equipment

4. Paper industry: raw water, white water filtration, protection nozzle

5. Central air conditioning system cooling water, condensate water, petrochemical industry, automobile manufacturing and other cleaning and filtration

Main specifications, technical parameters

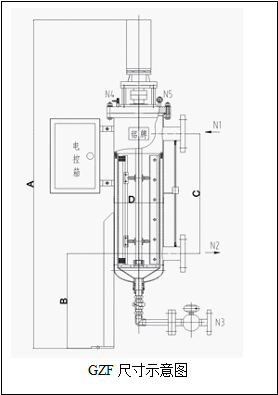

product model | A(mm) | B(mm) | C(mm) | D(mm) | Access and exit diameter (mm) | Outoutlet size (mm) | Reference Flow Rate (m3/h) |

GZF30 | 1500 | 450 | 500 | 219 | DN50 | DN25 | 30 |

GZF 50 | 1530 | 510 | 500 | 350 | DN100 | DN25 | 50 |

GZF100 | 1630 | 630 | 600 | 450 | DN125 | DN50 | 100 |

GZF125 | 1700 | 660 | 620 | 550 | DN150 | DN50 | 125 |

GZF150 | 1800 | 710 | 630 | 650 | DN200 | DN50 | 150 |

GZF180 | 1900 | 770 | 650 | 750 | DN250 | DN50 | 180 |

Note: If necessary, please consult our technical department for detailed technology. Besides, special specification filters can be customized according to customer requirements.

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI